BEHIND-THE-SCENES: ELECTRIC CAR CONVERSION PROCESS

Electric car conversion is an extremely exciting project here at Peace Vans. But before we proceed, it’s crucial to thoroughly evaluate the vehicle to ensure its suitability for conversion. This blog post will look at the key factors we consider and implement when considering an ev conversion.

Evaluate the Vehicle for electric car conversion

The first step of any electric car conversion process is for our technicians to comprehensively inspect the vehicle, where we look at the structural integrity, mechanical components, and space considerations. Nothing is worse than completing an expensive EV conversion, only to learn during the test drive that you must also overhaul your suspension system and brakes. We much prefer delivering that news up front and building it into the budget.

As part of our inspection process, we also look for signs of significant rust or other structural issues that might make the vehicle an unsuitable candidate for a conversion. A solid and rust-free base will provide a sturdy foundation for the electric conversion. We’ve had to talk people out of these projects due to poor previous repairs, safety considerations with added weight, or overall conditions due to rust.

Typically, before your vehicle arrives, we will have already discussed a battery configuration. But, during this inspection process, we will verify that the battery pack scoped will fit and work with the vehicle. Adequate space allocation will ensure a successful electric vehicle conversion without compromising on comfort or functionality.

Evaluate your needs

This step lays the foundation for a successful electric car conversion, considering factors such as budget, desired driving range on a single charge, and available space within the vehicle.

The two most important decisions to be made in this ev conversion stage are battery pack size and drive train/motor considerations. Needless to say, there are significant tradeoffs when evaluating. A larger battery pack will give you more range and increase the project's cost. We currently offer different motor/drivetrain options, which will also impact price and performance. Some customers want to maintain the stock transmission and ability to shift through the gears (fun!), and others prefer modern drivetrains in EVs, which replace your stock transmission.

Prep the car for ev conversion

Next, we prep the vehicle chassis. Decommissioning is key, removing your engine, gas tank & lines, engine accessories, and even the gas pedal. Once the old components have been successfully removed, we get the engine bay in tip-top shape. A power wash is often essential to eliminate any remnants of the past and create a blank canvas for your electric conversion. If a fresh coat of paint is needed, our team will do that during this process to make the engine bay shine. We love this phase, as working in a clean engine bay is so satisfying!

Design Parts

Next, we craft structural interfacing components that seamlessly connect the prepared chassis with the integral elements of the new electric tractive system. Depending on the vehicle, this task may include fabricating bespoke frames, mounts, or housings to secure the batteries seamlessly within the chassis framework. In some instances, the unique nature of our work may also require the creation of a custom motor mount. Our adept team has already created unique designs for several air-cooled VW models, with more on the way. We also partner with other leaders in the EV space to lower cost and time.

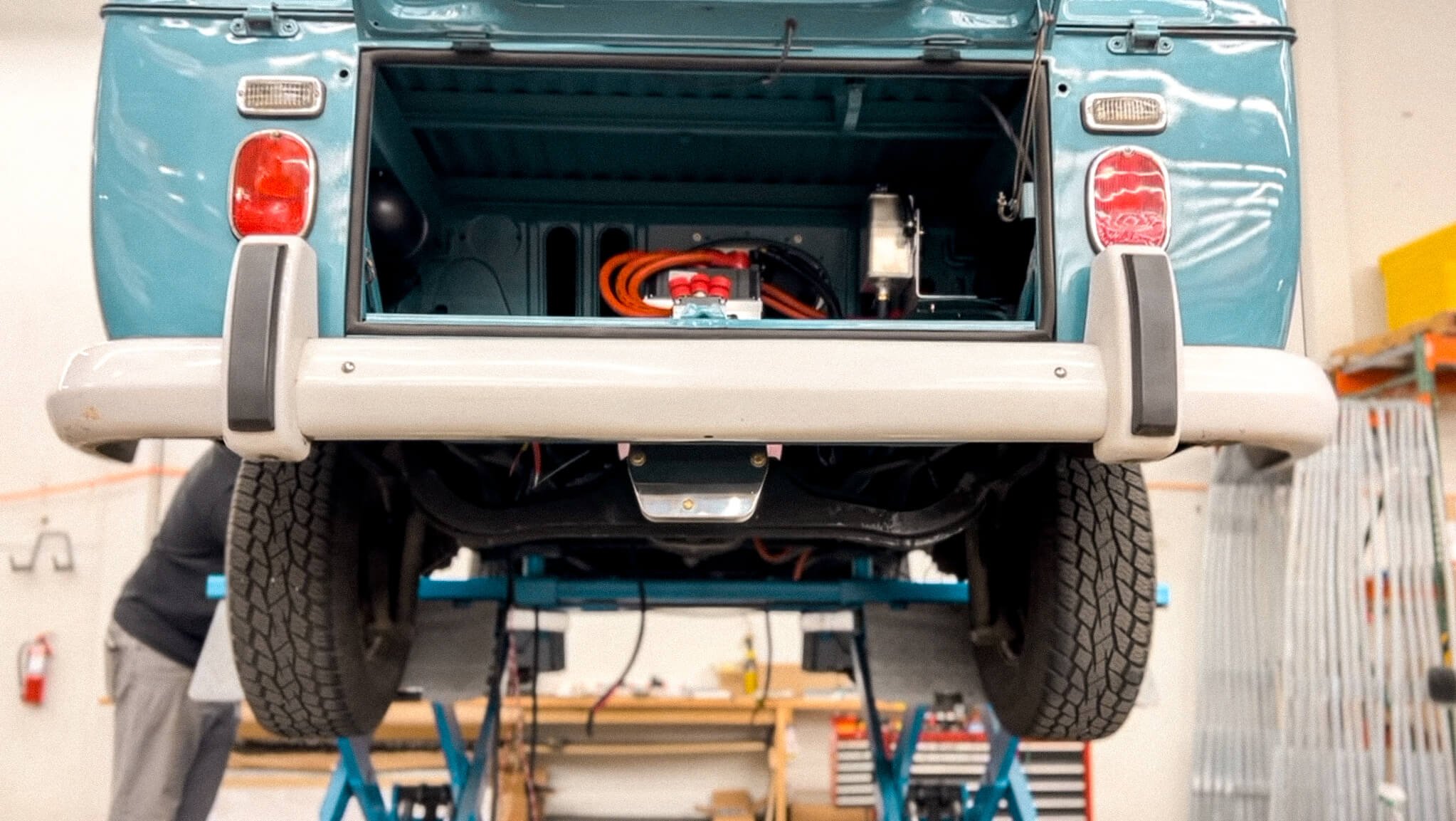

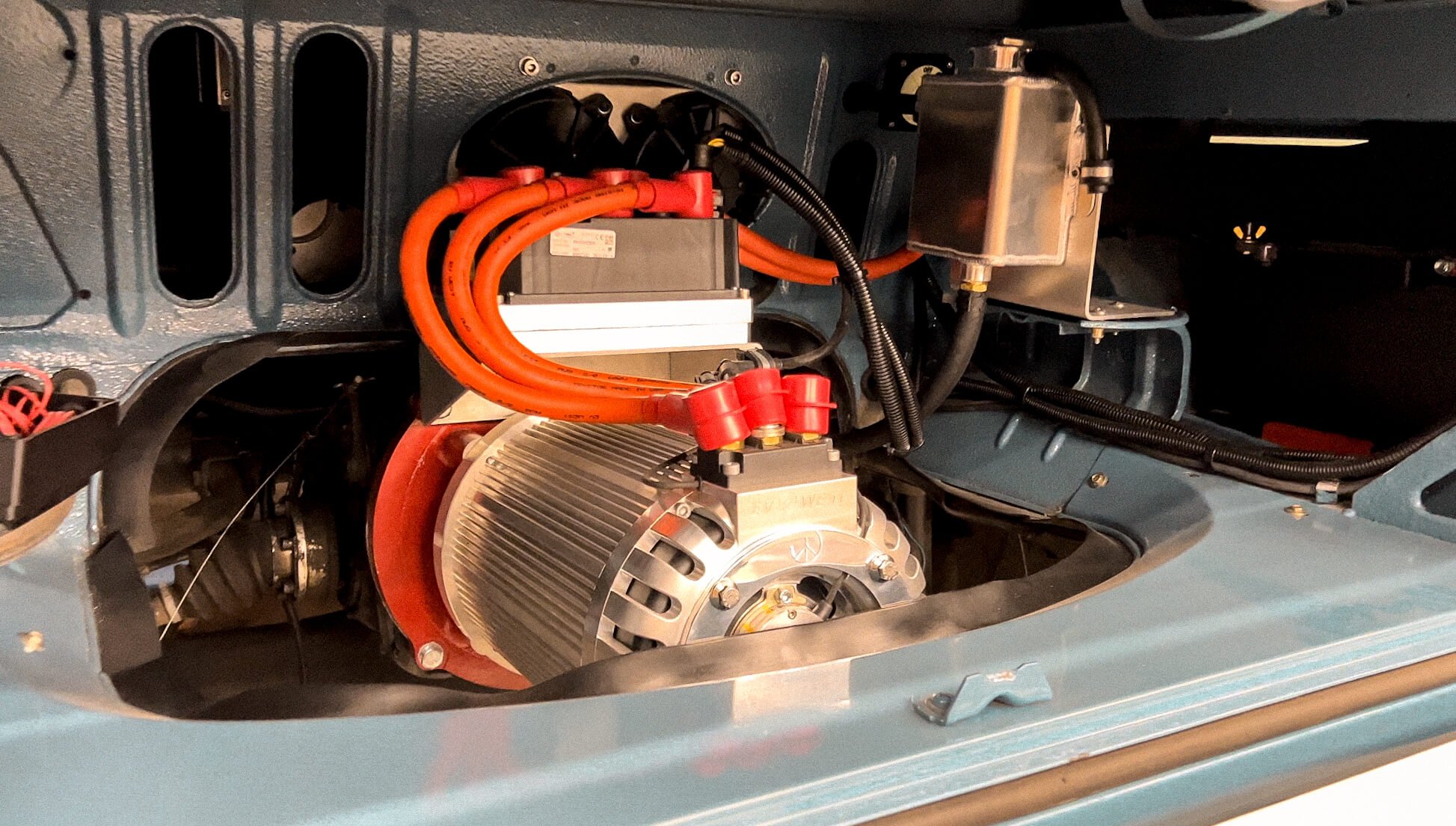

Install Structural & high-power components

Installing structural components involves setting up the battery frame or box, along with its mounts, to hold the battery in place securely. The transaxle housing adapter, input shaft coupler, motor, and corresponding mounts are also carefully installed to ensure proper alignment and integration with the existing chassis. Mounts and brackets are meticulously positioned to enable the functioning of various accessories, such as chargers and cooling systems.

High Voltage (HV) management is executed by utilizing high-current, fully isolated relays known as contactors. These contactors are crucial in maintaining your vehicle's safety and functionality. We will mount the contactors within a sealed enclosure, along with HV fuses, shunt(s) if required, a main disconnect switch, HV diodes, and other necessary elements. Our approach ensures optimal safety and protection for all HV components, guaranteeing a seamless and secure conversion.

Run High-Voltage (HV) Cable

The HV cable runs through your chassis and connects the battery pack to various components such as the contactors, motor controller, HV accessories [heater, dc-dc converter, charger(s)], and more. We carefully plan the route for the HV cable, taking into consideration the accessibility and safety of the wiring. Our team installs contactors along the HV cable, ensuring proper positioning and connection. These contactors act as computer-controlled switches, dictating the flow of high-voltage power to various components in the electric system. Once every component is connected, we conduct a thorough electrical check to verify the proper functioning of the HV circuit.

Install Additional Parts

These components, including chargers, DC-DC converters, heat exchangers, motor controllers, fans, and coolant pumps, are typically mounted into the engine bay. At the same time, cooling tubes are carefully routed through the engine bay and into the battery enclosure. This meticulous placement ensures effective heat management and optimal functionality of the converted electric vehicle, contributing to a smooth and reliable driving experience.

A significant transformation in this step involves replacing the conventional gas pedal with an electronic throttle, allowing seamless electronic motor control and responsiveness.

Wiring

Wiring plays a crucial role in the ev conversion process, particularly in battery management system (BMS) wiring. Due to its intricate nature, this conversion aspect alone can require a week of continuous work. The BMS monitors the voltages and temperatures of every parallel group of six cylindrical Panasonic 18650 battery cells within the Tesla modules. It determines when these cells can be charged or discharged, as well as when the cooling/heating systems turn on or off, ensuring their balance and preventing overheating. The BMS is not only crucial for a safe conversion, but it also significantly extends the lifespan of the batteries. Each battery module requires pinning 22 wires, installing two connectors, and carefully routing two branches of wiring.

Apart from the BMS wiring, the power distribution wiring also requires significant attention. The 12V system, serving various accessories, follows an involved setup. Before supplying power to each device, individual fusing is implemented. This power distribution is facilitated through a collection of relays, which the BMS, the motor controller, and other components control. Also, the 12V system supports multiple peripheral circuits responsible for tasks such as managing charging.

Many other wires must be installed for various functions. These include the electronic throttle, dash monitors, displays, buttons, sensors, the key-switch circuit, the charging port, and the CAN bus. The CAN bus is particularly important as it enables devices to communicate vehicle and battery information with one another digitally.

Programming

The battery management system and the motor controller must be carefully programmed. At Peace Vans, we set current limits, designate inputs/outputs for relay switching, charging, and more. Our team of experts also takes the time to finely tune the motor's behavior in response to throttle and brake inputs. This fine-tuning results in a driving experience that is both thrilling and smooth, ensuring that each ride in your converted electric vehicle is as enjoyable as possible.

Take the Build High Voltage

In this process of the electric car conversion, we suit up in high-voltage gear and connect the batteries to each other using strong nickel-plated copper busbars. Once the batteries are securely linked, we engage the main disconnect switch, turn the key, and eagerly await the high-frequency whir of the inverter. It's a thrilling moment, knowing that the power of electricity is flowing in your vehicle.

Instrumentation and Dashboard Mods

This is one of our favorite and most satisfying parts of the electric conversion process. Your new EV conversion can deliver as much data as you want, displayed in whichever visualization you, the driver, are partial to. We offer a myriad of configurations. Our team can maintain a 100% stock look and feel on your dash, making the stock gauges interface with new components to deliver information, such as the fuel gauge showing the remaining battery range. If that’s not your vibe, we can place custom in-dash mini screens that give you all sorts of real-time data and information on the performance and condition of your EV conversion.

Testing, Testing, and More Testing

Testing is a crucial final step in our process, ensuring your conversion is road-ready and meets the highest performance standards. Before hitting the road for the first time, our techs troubleshoot and fine-tune every conversion aspect. Once everything is in order, we subject the vehicle to rigorous testing, undertaking at least three cycles of driving until it reaches empty, then charging it to full capacity. This comprehensive testing enables us to evaluate critical parameters such as charging efficacy at public EVSE stations, ascending long and steep hills, maintaining adequate battery cooling, and keeping up with highway traffic. By conducting these tests, we can provide accurate and reliable real-world specifications for your conversion, including charging time, range, acceleration time from 0 to 60 mph, and more. The final testing phase ensures that your converted electric vehicle is primed for an exceptional, worry-free driving experience.

DELIVERY DAY

Most of our customers are from outside Seattle, so the delivery day is about you flying up to get a full rundown on the vehicle and ev conversion, test drive all you want and then prep for shipping home. Of course, you are also welcome to drive it home. This day is full of smiles and the best vibes imaginable.

Ready to convert your air-cooled VW to electric?

We’re here to make those dreams come true! Fill out our inquiry form, and our dedicated team will reach out to walk you through the entire process.